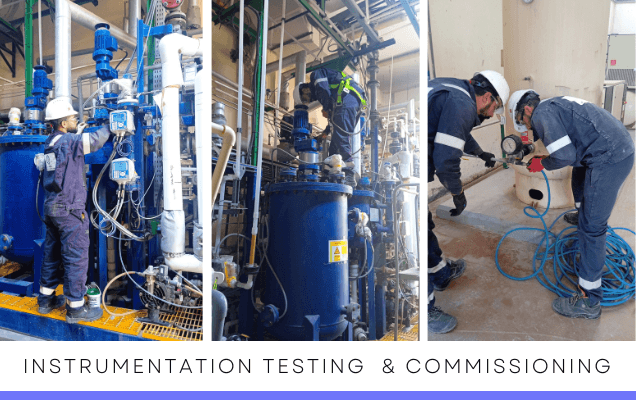

Instrumentation Testing and Commissioning involve the process of verifying and ensuring that instrumentation systems are correctly installed, calibrated, and functioning according to the design specifications and operational requirements. This typically includes testing of sensors, transmitters, control valves, and other field devices to ensure accurate measurement and control of processes. Commissioning is the final step in ensuring that all systems are integrated, functioning properly, and ready for operation, following safety and performance standards.

Reliable Instrumentation Systems and Services by SSE MULTINATIONAL

SSE MULTINATIONAL harnesses the expertise of its highly skilled instrumentation engineers and technicians to deliver reliable instrument systems and services. We specialize in providing comprehensive solutions to measure, monitor, and control processes, ensuring client satisfaction and acceptance.

Instrumentation Testing and Commissioning:

Our proficient team excels in testing and commissioning a wide range of instrumentation systems. Some of the areas we specialize in include:

Rely on SSE MULTINATIONAL for reliable instrumentation systems and services. Our experienced engineers and technicians ensure that your instrumentation systems meet the highest standards of performance and reliability. Contact us today to discuss your specific needs and benefit from our expertise.

At SSE Multinational, we believe that clear communication and expertise are key to successful project outcomes. That’s why we’re here to address any questions you may have—whether about our commissioning services, project strategies, or customized solutions. Our team of industry experts is dedicated to providing the insights and guidance you need every step of the way, ensuring confidence and clarity throughout your project journey. Reach out, and let us cover your questions with the answers you deserve.

The purpose is to ensure that all instrumentation systems (sensors, transmitters, controllers, etc.) are installed correctly, calibrated properly, and perform as expected to guarantee the accurate measurement, control, and safety of industrial processes.

Common instruments include sensors (temperature, pressure, flow, etc.), transmitters, control valves, pressure relief valves, and actuators used in various industrial applications such as oil & gas, power plants, and chemical processing.

Calibration is the process of adjusting an instrument to ensure its readings are accurate and consistent with a known standard. It is crucial for ensuring measurement precision and system reliability.

Performance is verified by conducting tests under normal operating conditions to check for accuracy, response time, and stability. The instrument must operate within specified parameters and tolerances to be considered fully commissioned

Safety is paramount during testing and commissioning, as instrumentation often involves systems that control hazardous processes. All tests must adhere to strict safety protocols to avoid accidents and ensure that the system operates safely in its intended environment.

Testing involves verifying individual instruments and their functionality, whereas commissioning is the overall process of integrating these instruments into a functioning system and ensuring it works as intended under real operating conditions.

This responsibility typically falls to skilled professionals such as instrumentation engineers, technicians, and commissioning specialists who have expertise in control systems, calibration, and system integration.

Detailed documentation is needed, including test plans, calibration certificates, inspection reports, and safety records. These documents verify that the system was tested thoroughly and meets all regulatory and operational standards.

Common challenges include incorrect installation, miscalibration, integration issues between different system components, and delays due to unavailable equipment or technical failures during tests. Proper planning and attention to detail can help mitigate these issues.