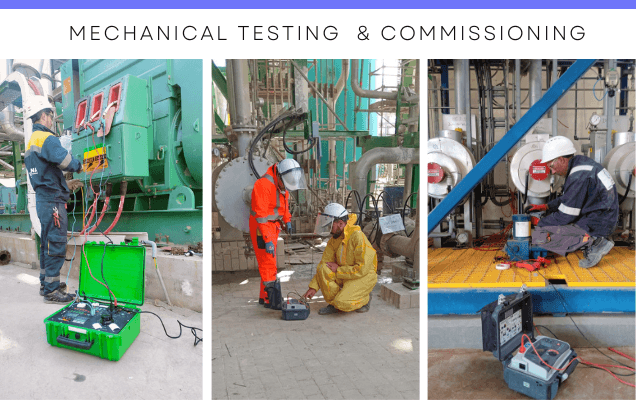

Mechanical Testing and Commissioning involve the process of verifying and ensuring that all mechanical systems and equipment, such as pumps, motors, turbines, piping, and HVAC systems, are installed, tested, and functioning according to design specifications. The goal is to confirm that the mechanical systems operate safely, efficiently, and reliably under real-world conditions. This includes checking alignment, integrity, performance, and system integration. Commissioning ensures that all mechanical components are fully operational, meet safety standards, and are ready for handover to the client or end-users.

At SSE Multinational, we believe that clear communication and expertise are key to successful project outcomes. That’s why we’re here to address any questions you may have—whether about our commissioning services, project strategies, or customized solutions. Our team of industry experts is dedicated to providing the insights and guidance you need every step of the way, ensuring confidence and clarity throughout your project journey. Reach out, and let us cover your questions with the answers you deserve.

The purpose is to ensure that mechanical systems, such as pumps, motors, piping, and HVAC, are installed correctly, tested for performance, and function as intended. The goal is to verify that systems are safe, reliable, efficient, and meet design specifications before they are handed over for full operation.

The first step is typically a review of the design documentation to ensure that all specifications are clear and that the mechanical systems are installed correctly. This may also include inspecting equipment upon arrival and ensuring it is in good condition.

Common tests include:

Hydrostatic testing involves filling pipes, tanks, or vessels with water to test for leaks and to verify the structural integrity of the system under pressure. This is a critical safety measure to ensure the system can withstand operating pressures.

Alignment testing is crucial to prevent wear and tear on bearings, shafts, and other rotating components. Proper alignment ensures that the mechanical systems operate efficiently, reducing the risk of equipment failure and extending the lifespan of the machinery.

System integration testing ensures that all mechanical systems, such as pumps, motors, and piping, work together seamlessly. It also includes verifying that the mechanical systems are properly integrated with electrical and control systems and that safety interlocks and control signals function as expected.

Final checks typically include:

Common challenges include:

Safety is ensured by conducting risk assessments, following safety protocols, using proper protective equipment, and ensuring that all safety devices (e.g., pressure relief valves, emergency shutdown systems) are tested and functioning properly. Additionally, personnel are trained on safe operational practices.

All tests, inspections, and certifications are documented in detailed reports, which include test results, operational parameters, and compliance with design specifications. This documentation is crucial for final client handover and future maintenance and troubleshooting. using proper protective equipment, and ensuring that all safety devices (e.g., pressure relief valves, emergency shutdown systems) are tested and functioning properly. Additionally, personnel are trained on safe operational practices.

HVAC systems are tested by checking air and water flow, temperature control, pressure drop across filters and coils, and the overall system’s efficiency. These tests ensure that the system maintains the required environmental conditions as specified in the design.

After commissioning, the system enters the operational phase. Maintenance training is provided to staff, and post-commissioning support may be offered to resolve any issues. Performance monitoring continues to ensure systems remain reliable and efficient throughout their lifecycle.